Official distributor in Russia and CIS countries

High Pressure Hydraulic Test Pumps

HP pumps for hydraulic testing of pressure equipment and systems

HII hydraulic test pumps help quickly and efficiently test various types of equipment in different modes.

Main types of tested equipment:

- Pressure vessels: cylinders, receivers, chemical reactors, tank trucks, tanks, pressure chambers, and boilers

- Tube-type, plate-type, and spiral-type heat exchangers

- Casings of pressure equipment: pumps, compressors, hydraulic cylinders, and drives

- Pipes and pipe assemblies, HP hoses and other types of hoses, flexible drill strings, and brake pipes

- Hydraulic, pneumatic, and gas supply lines

- Gas and oil pipeline sections, oil and gas equipment sections

- Stop valves, control valves, and pressure relief valves

- Valves of various types, including globe valves, gate valves, and ball valves

Main types of tests:

- Hydrostatic

- Cyclic

- Hydraulic fracturing, burst tests

- Leakage control

- Seat closure leak detection

- Adjustment of control and pressure relief valves

- Instrument calibration

For detailed description of HII pumps operation, application methods, and specific features of these pumps vs. electrically driven pumps for hydraulic testing, please refer to the "Pump Operation Procedure catalogue" (only Russian version available) located at "Download Catalogues" page.

Drive type: pneumatic

HII pumps of all series are pneumatically driven.

3L pumps (of the lowest flow rate) are equipped with a manual drive in addition to the pneumatic one. While operating 3L pumps, you do not have to switch over between the drives since both the pneumatic and manual drive are connected simultaneously. For 3L pumps functional diagram and operation description, please refer to the "Pump Operation Procedure" document.

HII pumps are not electrically driven, so such features as voltage class, electric power, and electric grid characteristics are not applicable to them.

For feeding the drives of HII pumps of all series, 5–10 bar oil-free industrial air is needed. The air shall contain no excessive moisture or mechanical impurities.

When pneumatically driven pumps are connected-up, no lubricator shall be installed in the air line since it is fatal for the drive.

The required air amount and the feeding compressor capacity depend firstly on the operation mode of a pump and varies from 0.1 to 10 m3/min.

For detailed information on the required air amount and quality, please consult our experts.

Hydraulic test pressures

Generally, the operation pressure range of the pumps is 0–4000+ bar. In this range, 99.9 % of hydraulic test objectives of engineering practice can be achieved. To achieve the rest 0.1 % of objectives, you can use HII one stroke intensifier, covering pressures up to 10,000 bar (150,000 PSI). This section does not cover one stroke intensifiers since they are used for very specific applications.

Each pump model has its own maximum operation pressure.

The minimum operation pressure for each pump model depends on specific features of its pneumatic drive. This value is especially important for hydraulic tests.

The minimum pressure of a pneumatic drive activation for a standard model is 1–2 bar. For a new pump, it is 1 bar, for a worn-out (but still operating) one, the minimum required pressure will grow up to 2 bar.

This minimum pressure value is the low limit of pressures at which a pump can run in “a pressure maintaining mode”.

"L" modification helps expand the pneumatic drive feed pressure range down to 0.2–0.3 bar and thus expand the operation pressure range limits.

In a constant flow operation mode, pumps of all series with no modifications will run faultlessly at any discharge pressures within pressure range starting from atmospheric.

Example. A pump builds up pressure from atospheric to 500 bar with an air drive pressure up to 5 bar (1:100). With air drive pressure below 1 bar, the pump will not start. It means that the pump will not be able to maintain test pressure below 100 bar. But when testing product at 500 bar, the pump will build up pressure gradually in the product from atmospheric to 500 bar without any limitations.

Flow range

Unlike all electrically driven positive displacement pumps that have a rated flow depending on a flow needed for a single shaft rotation and a shaft rotation speed, pneumatically driven pumps have no rated flow.

Furthermore, pneumatically driven pumps are not characterized with an operation flow range, unlike centrifugal pumps that have a flow range limited by 10 % of the rated flow value.

The pneumatic drive of the pump is operative within a speed range from 1 cycle per month to hundreds of cycles per minute.

There are some recommendations and methods for evaluating the service life of a pump in different operation modes.

It should be noted that any pneumatically driven equipment is designed for low speed and low flow applications.

Pneumatically driven pumps may be applied only within the following absolute limits:

- Discharge pressure of 0–86 bar: flow is 50 l/min max

- Discharge pressure of 86–700 bar: flow is 10 l/min max

- Discharge pressure of 700–1380 bar: flow is 5 l/min max

- Discharge pressure of 1380–4000+ bar: flow is 1–2 l/min max

These values are given for a single pump with a maximum capacity for this pressure class. For several pumps operating in parallel, the values will correspondingly increase.

The "Pump Operation Procedure" describes the methods of pump selection by flow in detail. However, the document covers only about 10 % of the information required for proper equipment selection.

Please consult our experts.

Pressure adjustment

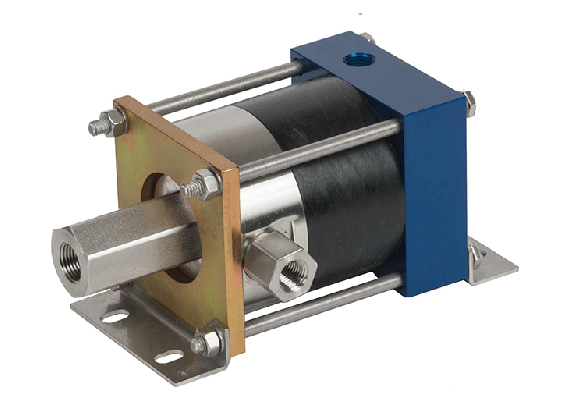

HII pumps are designed as air driven hydraulic pressure amplifiers.

It means that they multiply the air drive pressure by an Area ratio defined as a ratio of the pneumatic drive piston area to the plunger area.

The Area ratio is the main specification for the pumps of this type.

To adjust a pump discharge pressure, it is necessary to set up appropriate air drive pressure with a pressure reducer or an I/P controller.

The discharge pressure adjustment accuracy will depend on the accuracy of air drive pressure setting. Ideally, it is possible to reach a very smooth and stepless discharge pressure adjustment. For pumps with a high Area ratio, the adjustment accuracy is lower.

Pneumatically driven pumps have a very high setting pressure repeatability. For most of the models, you should set up the discharge pressure only once, without any additional manual setting or continuous automated adjustment to reach high accuracy of discharge pressure repeating.

This property is of great importance for cyclic tests and hydraulic testing of large-scale manufactured products.

Exception: 3L spring-return pumps. These pumps are not applicable when the pressure repeatability is important.

The "Pump Operation Procedure" provides a detailed description of the discharge pressure adjustment with relevant trends and examples.

Flow adjustment

The pneumatic drive of HII pump allows adjusting the pump rod speed in a complete range, from zero to maximum values.

However, it should be noted that the pneumatic drive will not provide a highly accurate and constant flow required for high-accuracy dosing and performance testing. For such applications, positive displacement pumps with fixed rated flows shall be applied.

For most of the hydraulic test objectives, a pump flow adjustment is not an essential factor.

For valve seat closure leak detection, flow meters are used. A pump should maintain the required valve pressure or differential pressure and “automatically” compensate leakages without any automation equipment. Pneumatically driven pumps are perfectly suitable for this application.

The "Pump Operation Procedure" provides a detailed description of the flow adjustment with relevant trends and examples.

Pneumatic drive of HII pump allows keeping a tested product under pressure for a long time without actual liquid flow. This prevents:

- Liquid heating during hydraulic test

- Liquid contamination with wear debris

- Air ingress

- Power loss

- High frequency flow fluctuation.

Due to the pneumatic drive and plunger-type design, HII pumps:

- Do not contaminate the handled liquid, so they are a perfect solution for hydraulic testing where high purity liquids are required

- Require no bypass valve or pressure-relief valve for pressure adjustment

- Require no VFD and provide “automated” control without any automation devices

- Provide an extremely smooth, fast, and easy flow and test pressure control in a wide range: from zero to max values

- Require no electric power supply

Furthermore, they are:

- Perfectly suitable for pressure adjustment applications: in some operation modes, these pumps are much more efficient than electrically driven equivalents

- Designed for unlimited number of start and shutdown cycles and are perfectly suitable for applications with high cyclic loads

- Resistant to water hammer effects caused by hydraulic fracture of the tested product

- Fire- and explosion-proof

- Continious dry run resistant having low NPSHr and high self-suction capabilities.

- Lightweight and compact

- Not applicable for handling contaminated liquids and liquids with mechanical impurities

- Restricted usage for high flow applications

- Much more expensive than the electrically driven equivalent solutions for such applications as flushing and pressure testing of equipment with a capacity of over 100 m3, as well as for pre-filling of large capacity equipment and systems, where high continuous flows are required

- Not fit for gas phase pumping

- Not fit for high accuracy dosing

- Pure water, industrial water, oily water, water containing corrosion inhibitors

- Distilled water, deionized water

- Industrial oils, hydraulic oils, aircraft oils, mineral oils, synthetic oils, motor oils, loom oils

- Break fluids, skydrol

- Hydrocarbons, solvents

- Antifreeze compounds, ethylene glycol, non-freezing liquids

- High-purity liquids

- Explosion and fire hazardous liquids

- Chemically active and aggressive liquids

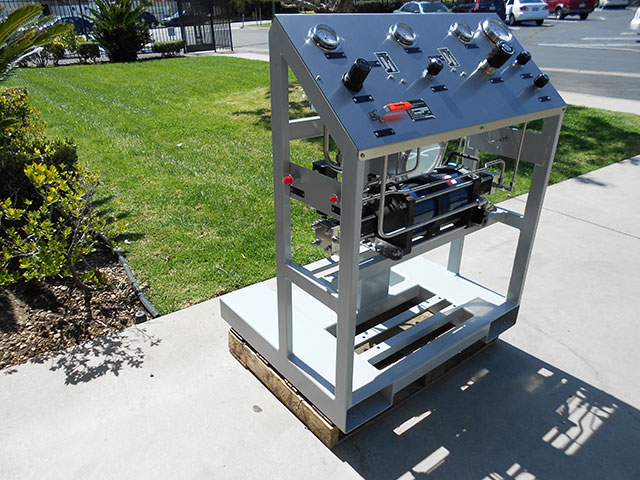

Hydraulic test benches

Test benches for hydraulic tests of high and ultra-high pressure equipment

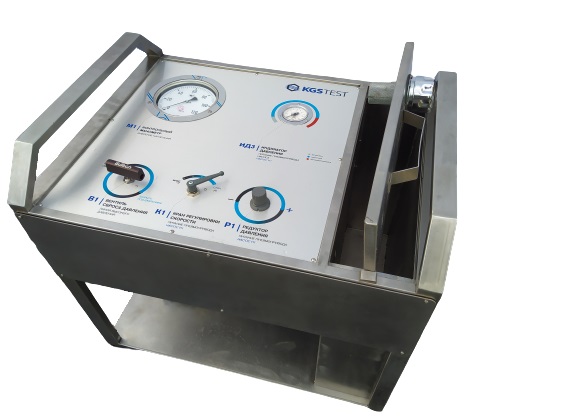

Pneumatic Test Benches

Pneumatic test benches for high pressure pneumatic testing with air or nitrogen

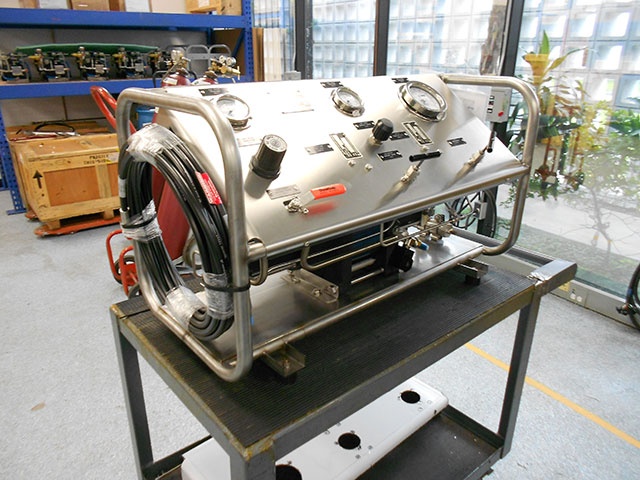

Test packs for Bodies and Assembiles Tests

Test packs for bodies assemblies tests of valves, vessels, hydraulic machines at production, service and repair stages

Test Package Rental

Rental of packages for hydraulic, pneumatic, and gas tests, including helium gas detection tests. Hydraulic stations, hydraulic test packages, compressors, and compressor packages

With pleasure we are informing you that we have launched a program for rental of high pressure and super high pressure hydraulic and compressor packages.

Our equipment is successfully used for the following applications:

- Static pressurization of vessels, tanks, and HP cylinders

- Calibration of safety devices

- Valve leak testing

- Safety valve adjustment

- Hydraulic tests of casing heads

- Hydrostatic tests of X-tree equipment

- Hydraulic and pneumatic tests of packer equipment

- Maintenance of ESP units

- Testing of pipe assemblies, pipelines, HP hoses, and hoses of other types

- Performance tests of equipment casings and valve bodies

- HP gas tests and helium gas detection tests with a helium-air mixture and helium-nitrogen mixture

A short-term rental of equipment will minimize your costs for single-time maintenance works and help you avoid keeping surplus stock of expensive highly specific equipment.

For a short-term rental, only attended packages are provided.

We provide for rental:

- HP hydraulic pumps: 0‒3000 bar

- Hydraulic test packages: 0‒3000 bar

- HP gas boosters: 0‒600 bar

- HP air boosters: 0‒600 bar

- HP helium boosters: 0‒600 bar

- HP nitrogen boosters: 0‒600 bar

- • Compressor stations, including multi-compressor solutions: 0‒600 bar

Rental of attended packages will prevent your equipment failure during its operation and minimize your time and money expenses.

With our long-term rented pump and compressor packages, you will be able to carry out your works in the most prompt and efficient manner.

In case of an attended package rental, you will have to pay only for actual package operation shifts, including installation, commissioning, and dismantling of the packages.

The delivery period of packages, accessories, tools as well as the time till our personnel`s arrival is not charged.

Rental of complex multi-compressor and multi-pump solutions is also available— please contact us for details.

For rental, we provide our own packages and packages subrented from third parties.

Expensive components (compressors and boosters of all types and HP pumps) and any systems based on them are provided against a deposit covering the 100 % cost of the packages.

Currently the fleet of packages to rent is just being formed, so there are some restrictions regarding the configuration of packages and the time of rendering services.

All types of packages available for rental have significant capacity restrictions. Their use for testing of large capacity equipment and systems is also restricted.

Compressors and compressor packages are non-greased. This results in their high wear during gas tests of large capacity equipment. Packages with an estimated wear over 10 % of the total wear are not provided for rental until they are overhauled.

Liquids:

- Pure water, service water, and water containing anticorrosive agents or antifreeze compounds

- Distilled water and deionized water

- With restrictions: liquids contaminating the pump wet end, including technical oils. The subsequent package washing is charged

Gases:

- High purity nitrogen, helium, helium-nitrogen mixture, helium-air mixture: no restrictions

- High purity air: no restrictions

- With restrictions: industrial air from an oil air compressor that is not fitted with a fine air cleaning system for oil removal. An additional cleaning system for the gas part may be provided at an extra charge as an option

- Freon gases, firefighting halons

The list of liquids and gases will be significantly increased with the rental program development.

Please let us know what packages you would like to rent currently and in the future. We need it to form the test package fleet more efficiently, minimize your costs, reduce your risks, and make our package rental even more available for you!