Multiphase booster pumps

Multiphase booster pumps for liquified gases handling

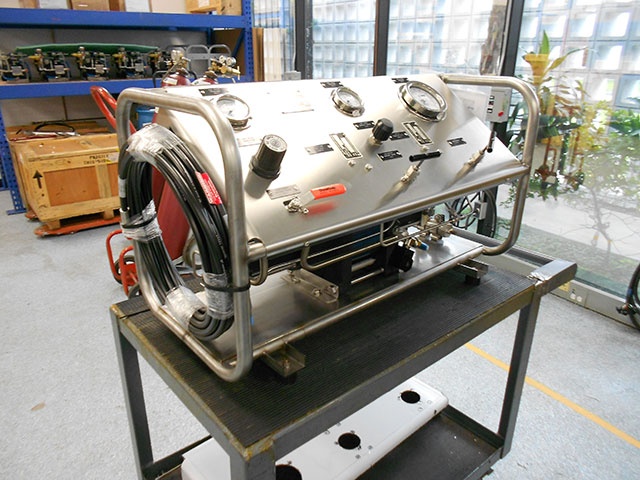

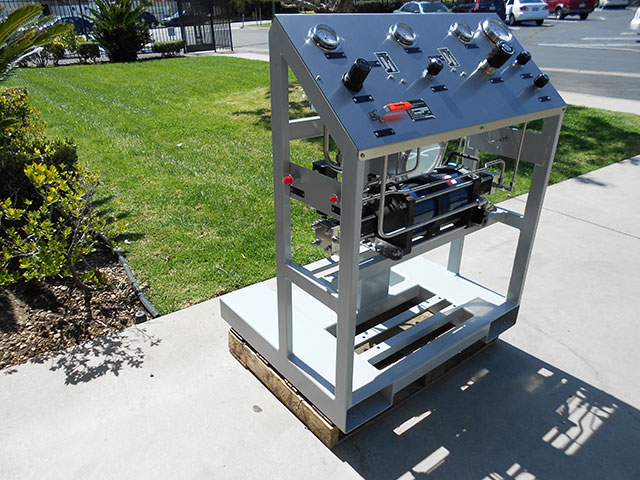

Multiphase booster pumps were developed by Hydraulics International Inc. specially for handling different liquified gases such as freons, halogens, CO2, LNG etc.

Multiphase boosters HII are designed for handling fluid in any phase from 100% gas phase to 100% liquid phase.

HII multiphase pumps basic line is represented with 5 models for solving standard tasks of liquified gases handling. This basic line can be supplemented with liquid pumps line and gas boosters line to handle any special engineering task.

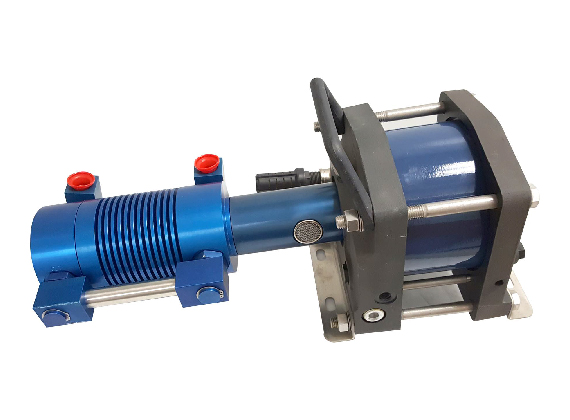

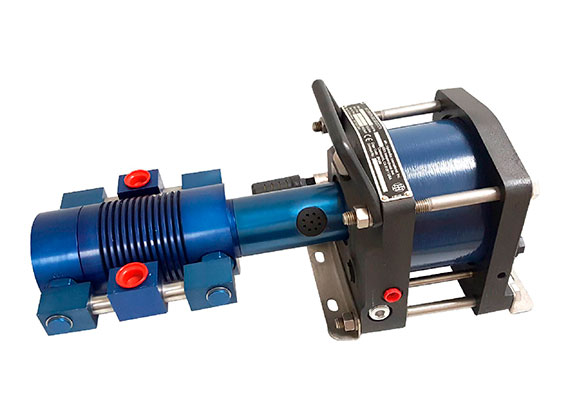

- Drive type: air driven;

- Discharge pressure range: 5 - 86 bar (70 - 1250 PSI) basic line, 2000 bar max. (30,000 PSI);

- Hydraulic part types: single-acting / double-acting;

- Number of stages: single stage, two stage;

- Inlet fluid phase: from 100% gas phase to 100% liquid phase

- Outlet fluid phase: from 100% gas phase to 100% liquid phase;

- Wetted parts lubrication: NO lubrication, no fluid contamination;

- Air drive lubrication: grease lubricant;

- Minimum gas evacuation level (model 5LG-TS-4): to 27” HG

- Minimum inlel gas pressure (other models): approx 3 barg;

- Maximum inlet fluid pressure (liquid or gas): equal to max. discharge pressure.

- Сlean design of the all wetted parts - no lubricats, no fluid contamination, ideal for handling high-purity fluids;

- Ideal for charging, maintaining constant pressure, recharging, gas evacuation;

- Unlimited start and stop cycles - from stend-by pressure maintenance operation to hard cyclic operation;

- Smooth and simple pressure adjustment in a wide pressure ranges from 0 to MAX;

- Fire and explosion proof;

- No electrical parts;

- Compact and lightweight - mobile design;

- Designed for handling fluid in any phase from 100% gas phase to 100% liquid phase;

- Positive suction / cavitational restrictions do not exist by definition;

- Possibility of gas liquefaction by pressure;

- Possibility of gas evacuation to moderate vacuum;

- Inert to dust, moisture, weather conditions.

- Not designed for handling fluids, contaminated with mechanical impurities;

- Flow restrictions - not designed for high flows.

Various liquefied gases:

- Freons;

- Fire extinguishing refrigerants;

- Liquefied fire extinguishing agents;

- Foaming agents, blowing agents, pore agents;

- Propellants, foamers; < /li>

- Sulfur hexafluoride SF6;

- Methane R50;

- Propane R290;

- Butane R600;

- Isobutane R600a;

- Nitrous oxide N2O;

- Ammonia R717;

- Liquefied natural gas LNG.

Main types of pumped refrigerants:

- CFC`s: R-11, R-12, R-13, R-111, R-112, R-113, R-113а, R-114, R-115;

- Bromofluorocarbons: R-12B1, R-12B2, R-113B2, R-13B2, R-13B1, R-21B1, R-22B1, R-114B2;

- HCFC`s: R-21, R-22, R-31, R-121, R-122, R-123, R-124, R-131, R-132, R-133, R-141, R-142в, R-151, R-221, R-222, R-223, R-224, R-225, R-231, R-232, R-233;

- HFC`s: R-23, R-32, R-41, R-125, R-134, R-143, R-152, R-161,R-227, R-236, R-245, R-254;

- CF`s: R-14, R-116, R-218, R-C318.