Air Amplifiers

Air and nitrogen pressure amplifiers

Description

Air pressure amplifiers and packages HII are widely used worldwide for assisting air powered tools and machines, charging tires, pneumatic tests when powered from an air source or low-pressure air or nitrogen.

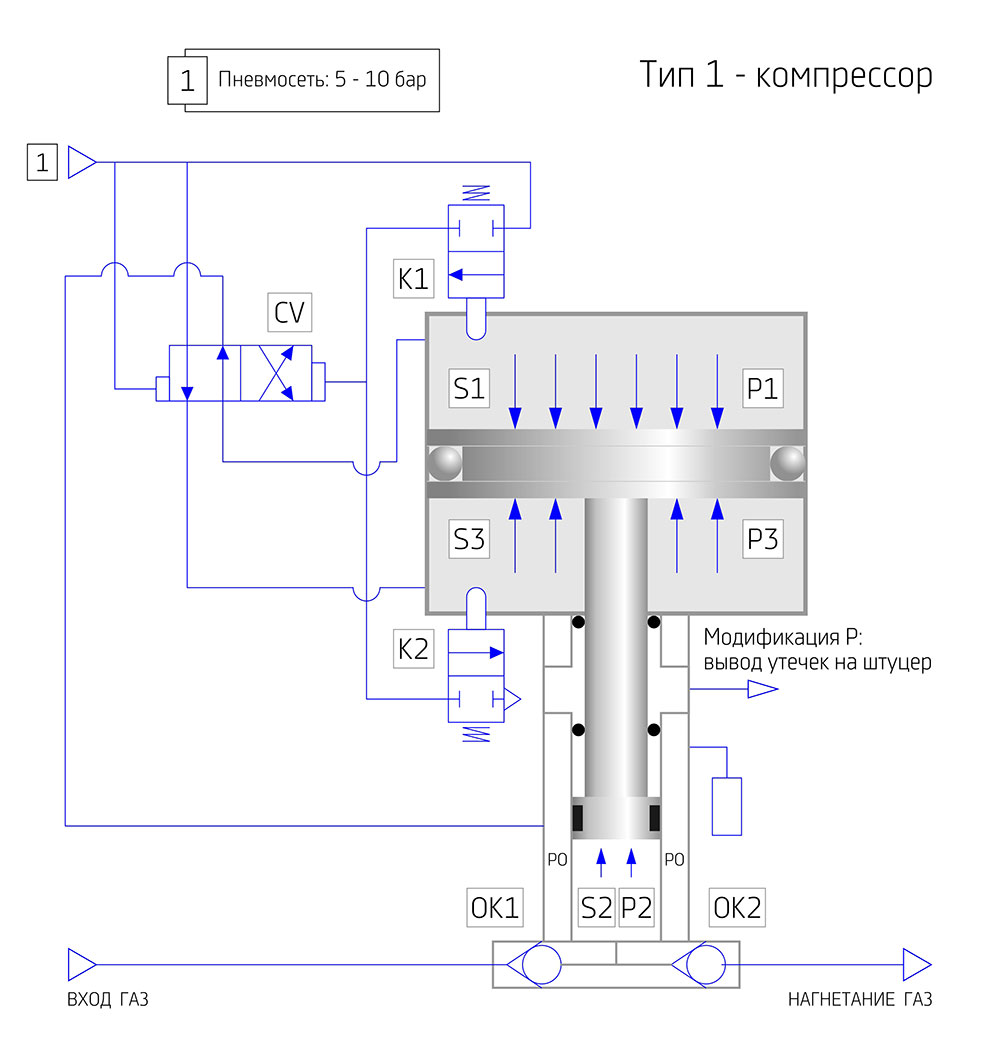

Compressed gas – air or nitrogen- is used to power the pneumatic drive of the amplifiers.

The line of pneumatic amplifiers is presented by 5 basic models as the standard solution of variety of engineering tasks of air or nitrogen pressure amplification from low pressure pneumatic line, atmospheric air compressor or the nitrogen generator.

Standard packages are presented with 4 standard configurations, including models on high pressure air receivers.

Air pressure amplifiers HII are simple, high-quality, cost-effective solution of supplying industrial air or nitrogen.

Features

- Drive type: pneumatic from gas source;

- Outlet pressure range: 5 - 86 bar (70 - 1250 PSI);

- Gas section type: oil-free - low air contamination;

- Number of gas sections: single-piston / double-piston;

- Number of compression stages: single stage / two stage;

- Air drive lubrication: grease;

- Minimum inlet pressure is determined by air amplifier model, but not less than 2 barg (30 PSI);

- Maximum inlet pressure is determined by air amplifier model, normally equal to the maximum outlet pressure;

- Maximum flow is determined by air amplifier model as well as the operating mode;

- Pneumatic drive requirements: industrial air, nitrogen 2-10 bar (30-150 PSI);

- Outlet pressure adjustment: smooth, continious, average to high accuracy, over a wide range of operating pressures;

- Gas flow rate adjustment: smooth, continuous, over a wide range of flows, low/medium accuracy.

Advantages

- Ideal for Air/Nitrogen charging, Air/Nitrogen pressure hold, recharging, pneumatic testing;

- Unlimited start/stop frequency - designed for operation under severe cyclic loads;

- Pressure and flow adjustment: smooth, simple, continious, in a wide range from 0 to MAX;

- Fire and explosion proof;

- No electric supply required;

- Manual or automated control: very simple, does not require high qualification of the operator;

- Compact and lightweight.

Restrictions

- Minimum inlet air pressure restrictions depending on amplifier model;

- Not designed for boosting pure and high-purity gases - allow contamination of pumped gas with the traces of drive air/nitrogen:

- Not designed for boosting hazardous gases, breathing gases, oxygen, hydrogen;

- Not designed for boosting contaminated gases, gases with mechanical impurities;

- Gas flow restrictions - not designed for high air flows;

Fluids

- Industrial air

- Industrial nitrogen