High Pressure Gas Boosters and Packages

High pressure gas booster packages, gas charging systems

Description

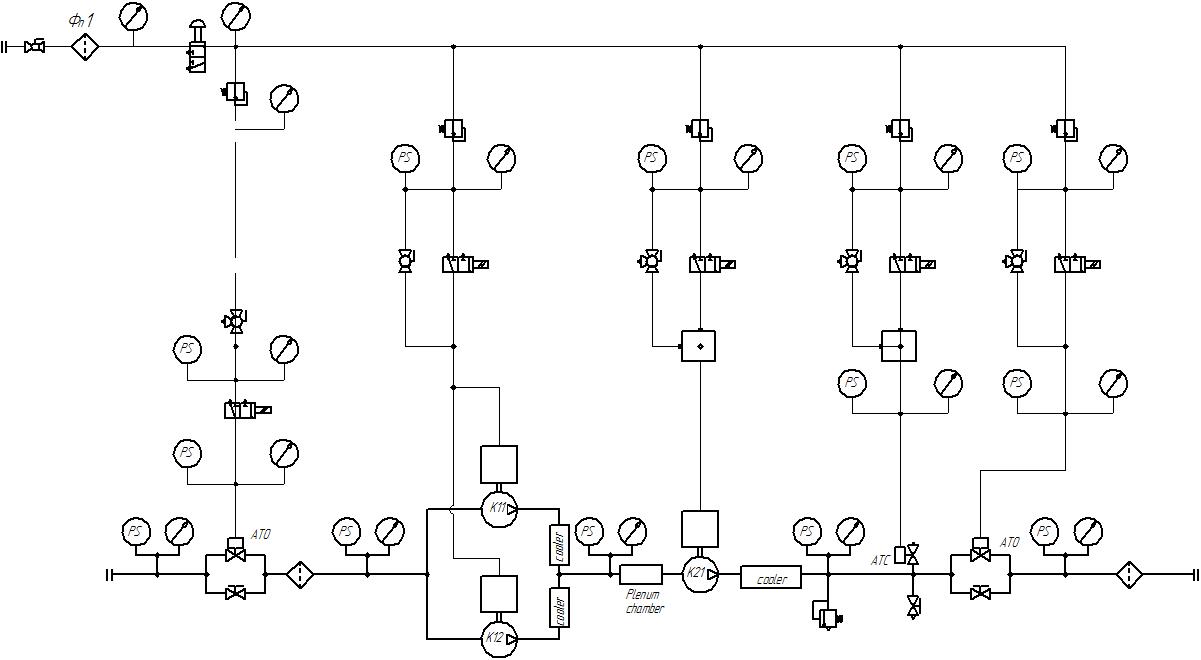

HII gas booster packages with pneumatic and electric drive allow to boost industrial and pure gases to high and ultra high pressures.

Pneumatically driven models are ideal for boosting flammable and explosive gases except acetylene.

Standard packages line consisting of 7 basic models is ideal to solve relatively simple tasks within a limited budget.

Customized HII solutions designed to customer's specifications, including multi-booster packages, significantly widen a range of tasks related to boosting gases at high pressures.

Features

- Drive type:pneumatic / electric (with built-in air compressor) / hand operated (based boosters 3G series);

- Outlet pressure ranges from 10 to 2000 bar (150 - 30,000 PSI);

- Gas booster`s gas section type: oil-free - does not contaminate supplied gas;

- Minimum inlet pressure is determined by gas booster model(s), but not less than 3 bar (40 PSI);

- Maximum inlet pressure is determined by gas booster model(s), normally equal to the maximum outlet pressure;

- Maximum gas flow depends on the number and types of gas boosters, as well as the operating mode;

- Pneumatic drive requirements: industrial oil-free air, nitrogen 5-10 bar (70-150 PSI);

- Special versions of pneumatic drives: associated petroleum gas driven, natural gas driven;

- Outlet pressure adjustment: smooth, continious, average to high accuracy, over a wide range of operating pressures;

- Gas flow rate adjustment: smooth, continuous, over a wide range of flows, low/medium accuracy.

Advantages

- Clean design of the gas booster`s gas section(s) as well as valves and fittings - no grease, no oil, no contamination;

- Special cleaning of all gas-contacting parts for treating high-purity gases, oxygen, hydrogen etc.;

- Ideal for gas charging, pressure hold, recharging;

- Unlimited booster start/stop frequency - designed for operation under severe cyclic loads;

- Pressure and gas flow adjustment: smooth, simple, continious, in a wide range from 0 to MAX;

- Fire and explosion proof;

- Manual or automated control: very simple, does not require high qualification of the operator;

- Compact and lightweight.

Restrictions

- Power packages are based on gas boosters: minimum inlet gas pressure restrictions depending on gas booster model(s);

- Not designed for filling high pressure gas cylinders with natural gas from a low-pressure household gas line;

- Not designed for boosting contaminated gases, gases with mechanical impurities;

- Gas flow restrictions - not designed for high flows;

- Maximum safe outlet pressure for Oxygen service: 365 bar;

- Maximum safe outlet pressure for Air service: 700 bar. If necessary to boost gas to higher pressures, oxygen-free gases shall be applied.

Fluids

- Industrial air, Nitrogen, Argon, Helium;

- Pure and high purity gases: Oxygen, Hydrogen, high purity Nitrogen, Helium, Argon, Krypton, Xenon,

- Breathing gases: Oxygen, Nitrogen, Air, gas mixtures, Nitrox, Heliox, Trimix;

- Searching gases: Hydrogen, Helium;

- Hazardous, flammable, explosive gases;

- Hydrocarbons except Acetylene: Natural gas, Synthesis gas, Propane, Butane, Methane, Ethylene, associated petroleum gas etc.

Didn't find the required gas in the list?

Send us request and our experts will check the compatibility of the equipment with the required gas.