Official distributor in Russia and CIS countries

Compressors for oxygen O2 supply

Description

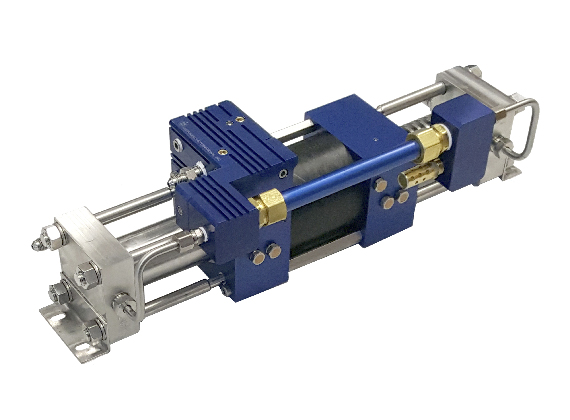

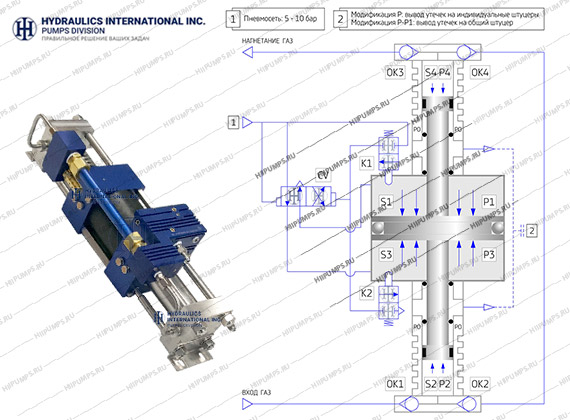

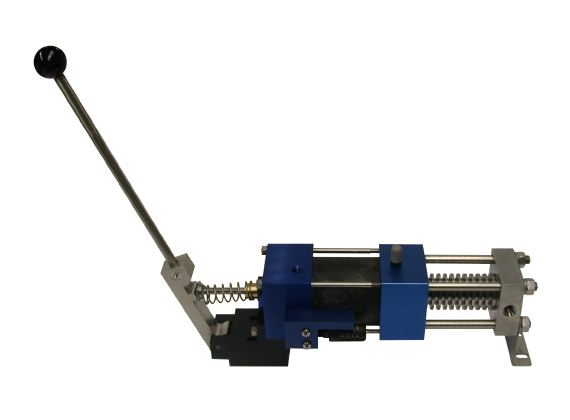

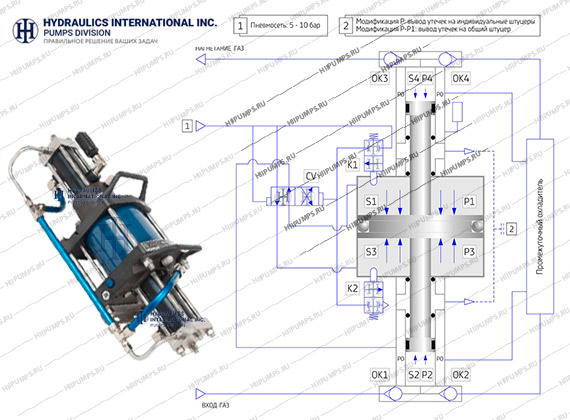

HII oxygen supply compressors allow you to boost oxygen of any purity classes to supply gas to the process, power equipment, charge high-pressure tanks and charge cylinders.

Oxygen can be supplied from an oxygen generator, an oxygen cylinder, a low-pressure line.

The gas end of the booster is stainless steel, gas seals are oil-free, the compressor part is cleaned according to ASTM G93-96 and CGA-4.1 standards, which guarantees the safety of the compressor when operating on oxygen.

The air drive of the booster accepts industrial air with a pressure of up to 10 bar.

Air drive end is separated gas end by a double seal with an intermediate unloading chamber, which completely eliminates the ingress of drive air into the compressor part.

The booster is fire and explosion-proof.

In addition to oxygen, boosters can supply various gas mixtures used in industrial production and diving.

Gas booster systems

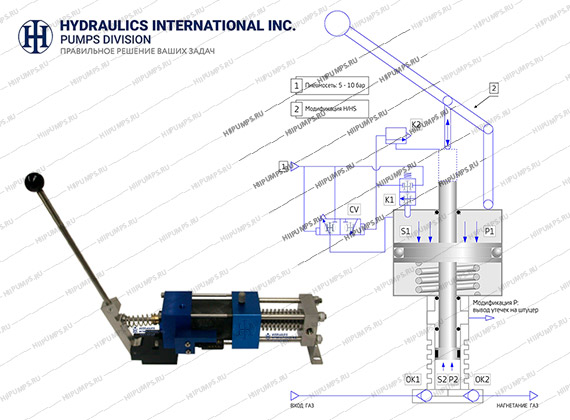

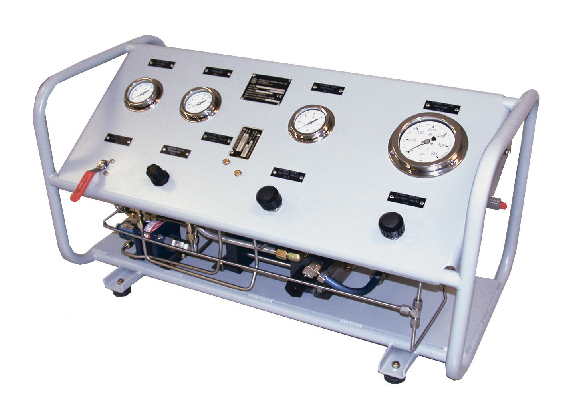

Gas booster systems for oxygen handling are manufactured by the HII on the basis of oxygen boosters.

The units include controls for the pneumatic drive of the compressor, shut-off and control valves, means of indicating and measuring pressure.

Booster systems do not require additional installation and commissioning work. The "plug and play" principle is implemented.

Systems are available in mobile and stationary versions.

Features

- Drive type: air-driven;

- Type of gas part: single-piston / double-piston;

- Number of stages: single-stage / two-stage;

- Lubrication of the gas part: dry, oil-free-works without lubrication, does not pollute the pumped gas;

- Requirements for the lubrication of the pneumatic drive: grease;

- Discharge pressure range from 10 to 360 atm (1-36 MPa);

- The minimum inlet pressure is determined by the compressor model, but not less than 3 atm;

- The maximum inlet pressure is determined by the compressor model, as a rule, it is equal to the maximum discharge pressure;

- The maximum performance for each model is different and depends on the operating mode;

- Pneumatic drive power supply: industrial air, nitrogen 5-10 atm (0.5-1.0 MPa);

- Special versions of the drives: powered by associated petroleum gas, methane, etc.;

- Pressure control: smooth, stepless, medium / high accuracy, in a wide range of operating pressures;

- Flow control: smooth, stepless, low/medium accuracy, in a wide range of flow rates.

- Cleaning according to ASTM G93-96 and CGA-4.1 standards

Advantages

- Absolutely clean design of the gas part - no lubrication;

- Do not pollute the gas - ideal for pumping high-purity gases;

- Ideal for charging, maintaining constant pressure, recharging;

- Unlimited number of start-up and stop cycles-resistant to hard cyclic load modes;

- Adjustment: smooth, simple, in a wide range from 0 to MAX;

- Fire and explosion-proof;

- No electrics;

- Compact and lightweight-a mobile solution.

Restrictions

- HII compressors are booster compressors: for the compressor to work, it is necessary to ensure that the oxygen pressure at the inlet is not lower than the minimum required;

- They are not intended for pumping contaminated gases, gases with mechanical impurities;

- Low-speed equipment - restrictions on maximum performance;

- Maximum safe oxygen injection pressure: 365 atm;

Types of gases

- High-purity technical oxygen

- Extra pure oxygen

- Oxygen grade 3.5; 5.0; 6.0

- Laser oxygen

- Medical oxygen

As well as other gases:

- Gases of high and ultrahigh purity: hydrogen, nitrogen, helium, argon, krypton, xenon, gases of grade 5.5, 6.0;

- Respiratory gases: oxygen, nitrogen, air, respiratory mixtures, nitrox;

- Searching gases: hydrogen, helium;

- Dangerous, fire-hazardous, explosive gases;

- Hydrocarbons, except acetylene: natural gas, synthesis gas, propane, butane, methane, ethylene, carbon monoxide, associated petroleum gas;

Seller's responsibility

Oxygen booster compressors and installations based on them are high-risk equipment.

Each request for this type of equipment is processed by our highly qualified specialists on an individual basis.