Official distributor in Russia and CIS countries

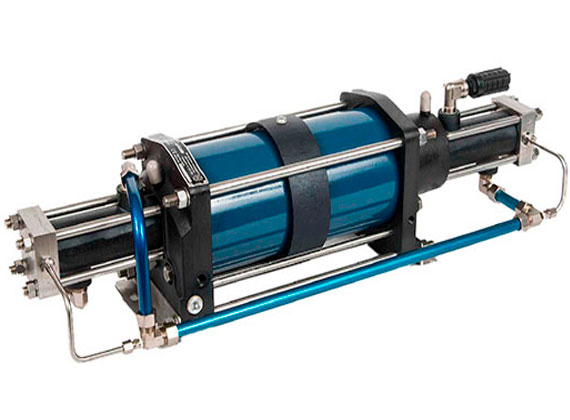

HII Gas Boosters for Hydrogen H2 handling

Features of hydrogen transfer.

When selecting equipment and fittings for hydrogen applications, the following features must be taken into account:

- Hydrogen has high fluidity, penetration abilities due to small molecule size. It is necessary to use special seals for hydrogen applications.

- Mixed with oxygen, hydrogen forms fire damp. It is necessary to vent possible gas leaks.

- Hydrogen embrittlement of all carbon steels, including stainless steels, under high pressure and at elevated temperatures must be considered during operation. Recommended service life of hydrogen gas part - no more than 7 years.

General recommendations for selecting HII hydrogen boosters.

Almost all basic models of HII hydrogen gas boosters are suitable for hydrogen supply except for single models.

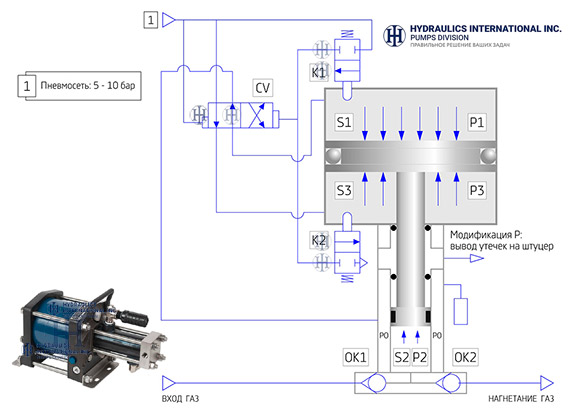

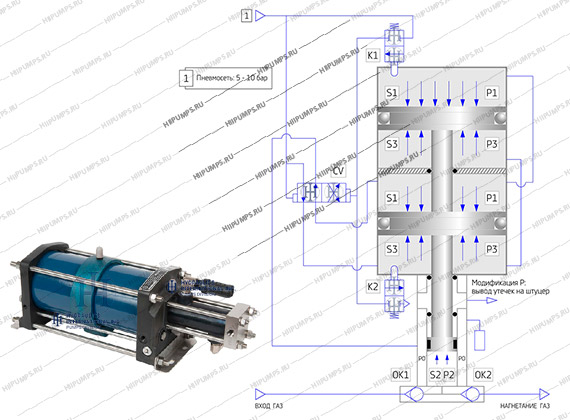

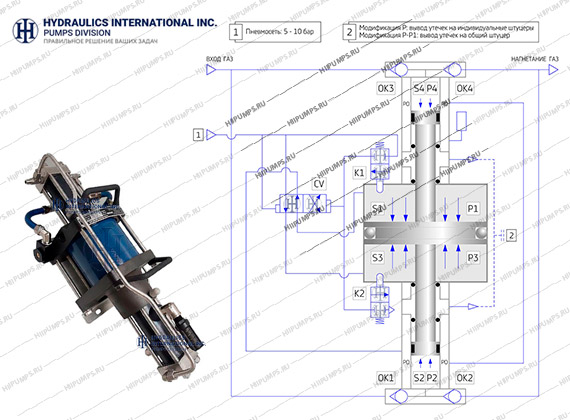

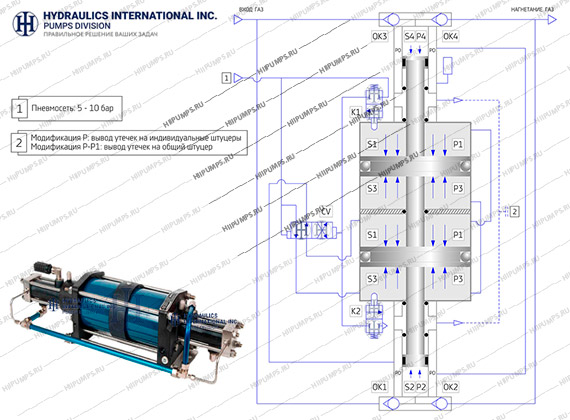

Special seal materials for hydrogen operation: modification "-H2"

Special version for venting hazardous gases to a safe area: modification "P" for models with single gas section, modification "P-P1" for models with two gas sections.

All HII booster models are non-lubricated: The gas part works without any lubricant (dry friction). It is physically impossible to contaminate the gas with grease.

For ultra-high purity hydrogen boosting, we also recommend providing a "-O2" oxygen feed modification. Additional cleaning of the gas section according to ASTM G93-96 and CGA-4.1 is performed by the factory.

ATTENTION: models on this page include modifications for hydrogen supply, the specifications for the basic models will show the names in the basic version.

Hydrogen supply to the product/process from a cylinder with an initial pressure of 150 bar (2200 PSI).

The feature of this task is the constant reduction of gas inlet pressure while discharging the cylinder.

The optimal booster type, the number of boosters connected in series and/or in parallel, will primarily be determined by the minimum inlet pressure, also considering the required capacity.

The lowest discharge pressure will be determined primarily by economic factors, as well as technical feasibility and time-related factors.

A few years ago it was not economically feasible to save almost any cylinder gas below 30 to 50 bar. Gas seal lifetime calculations showed a higher cost of booster seal replacement relative to the cost of the lost gas. Currently, the situation has changed dramatically, and gas seal lifetime calculations show acceptable return on investment when saving gas at pressures as low as 5 bar or even lower.

| Model type | Outlet pressure range POUT | Gas cylinder pressure range PIN (Inlet gas pressure) |

|

|---|---|---|---|

| Start discharging | Stop discharging | ||

| Single stage single acting gas boosters 5G-SS series with the single air drive Compression ratio: 1...6 |

|||

| 5G-SS-30-P-H2 | PIN ... 300 bar | 150 bar | 30...50 bar |

| 5G-SS-50-P-H2 | PIN ... 500 bar | 150 bar | 50...100 bar |

| 5G-SS-75-P-H2 | PIN ... 750 bar | 150 bar | 75...100 bar |

| Single stage single acting gas boosters 5G-SD series with the double air drive Compression ratio: 1...6 |

|||

| 5G-SD-60-P-H2 | PIN ... 600 bar | 150 bar | 75 ... 100 bar |

| 5G-SD-100-P-H2 | PIN ... 1000 bar | 150 ... 300 bar | 150 ... 300 bar |

| 5G-SD-150-P-H2 | PIN ... 1500 bar | 150 ... 300 bar | 150 ... 300 bar |

| Single stage double acting gas boosters 5G-DS series with the single air drive Compression ratio: 1...6 |

|||

| 5G-DS-30-P-P1-H2 | PIN ... 450 bar | 150 bar | 30 ... 50 bar |

| 5G-DS-50-P-P1-H2 | PIN ... 650 bar | 150 bar | 50 ... 100 bar |

| 5G-DS-75-P-P1-H2 | PIN ... 900 bar | 150 bar | 75 ... 100 bar |

| Single stage double acting gas boosters 5G-DD series with the double air drive Compression ratio: 1...6 |

|||

| 5G-DD-28-P-P1-H2 | PIN ... 400 bar | 150 bar | 30 ... 50 bar |

| 5G-DD-60-P-P1-H2 | PIN ... 750 bar | 150 bar | 50 ... 75 bar |

| 5G-DD-100-P-P1-H2 | PIN ... 1034 bar | 150 bar | 100 ... 150 bar |

| 5G-DD-150-P-P1-H2 | PIN ... 2068 bar | 150 ... 500 bar | 150 ... 500 bar |

Important rule for single-stage gas boosters application: compression ratio per one stage POUT:PIN should not exceed 6...8, the optimal range: 1...6.

Considering this rule, the table shows that for many high-pressure models, the required minimum inlet gas pressure is equal to or greater than the cylinder pressure. In this case, it is necessary to install two (or more) single-stage boosters in series or to use two-stage models (see "two-stage hydrogen boosters" below).

Which model to be choosen for a one stage boosting?

When choosing between single acting and double acting gas boosters (SS and SD models and DS and DD models, respectively), the following rules should be considered

- Single acting models are significantly cheaper.

- Single acting models can be set to hold a constant discharge pressure regardless of the inlet pressure. All other types will not allow this - in some cases it is necessary to install a reducer on the discharge.

- Single acting models are extremely inefficient in using the gas inlet pressure, their performance is significantly lower than all other models (DS, DD as well as TS, TD), and air consumption is much higher.

- Double acting models (DS models and especially the DD models) are the most efficient of the entire HII compressor range. They provide the highest possible capacity and lowest possible air consumption over a wide range of inlet pressures

For occasional charging of small and ultra-small vessels, the inexpensive SS or SD models are optimal.

For heavy-duty applications, the DS, DD models should be used.

| Model | Outlet pressure range POUT | Gas cylinder pressure range PIN (Inlet gas pressure) |

|

|---|---|---|---|

| Maximum reduced inlet pressure at stall conditions PIN max ( |

Minimum inlet pressure PIN min. |

||

| Two stage gas boosters 5G-TS series with a single air drive Compression ratio: 6...40 |

|||

| 5G-TS-7/30-P-P1-H2 | PIN ... 380 bar | 21 bar | 3.4 bar |

| 5G-TS-7/50-P-P1-H2 | PIN ... 400 bar | 10 bar | 3.4 bar |

| 5G-TS-14/30-P-P1-H2 | PIN ... 580 bar | 130 bar | 7 bar |

| 5G-TS-14/50-P-P1-H2 | PIN ... 700 bar | 55 bar | 7 bar |

| 5G-TS-14/75-P-P1-H2 | PIN ... 900 bar | 30 bar | 5 bar |

| 5G-TS-30/50-P-P1-H2 | PIN ... 1034 bar | 490 bar | 10 bar |

| 5G-TS-30/75-P-P1-H2 | PIN ... 1275 bar | 210 bar | 7 bar |

| 5G-TS-30/92-P-P1-H2 | PIN ... 1380 bar | 150 bar | 7 bar |

| 5G-TS-50/92-P-P1-H2 | PIN ... 2068 bar | 650 bar | 10 bar |

| Two stage gas boosters 5G-TD series with a double air drive Compression ratio: 6...40 |

|||

| 5G-TD-14/28-P-P1-H2 | PIN ... 310 bar | 145 bar | 17 bar |

| 5G-TD-14/60-P-P1-H2 | PIN ... 620 bar | 41 bar | 5 bar |

| 5G-TD-28/60-P-P1-H2 | PIN ... 620 bar | 262 bar | 10 bar |

| 5G-TD-28/100-P-P1-H2 | PIN ... 1034 bar | 110 bar | 20 bar |

| 5G-TD-28/150-P-P1-H2 | PIN ... 1830 bar | 62 bar | 20 bar |

| 5G-TD-60/100-P-P1-H2 | PIN ... 1034 bar | 206 bar | 41 bar |

| 5G-TD-60/150-P-P1-H2 | PIN ... 2068 bar | 440 bar | 35 bar |

Recommendation #1: Gas compression ratio POUT:PIN shouldn't exceed 36...64 per two compression stages, optimal ratio is 6...40.

Recommendation #2: inlet pressure shouldn't exceed interstage stall pressure.

Interstage stall pressure value will depend on air drive pressure. The maximum estimate PIN value is indicated in a table above.

In case the inlet pressure PIN exceeds stall pressure, inlet gas pressure reducer shall be installed.

The maximum allowable inlet pressure, limited by the strength of the inlet gas section, is usually significantly higher than the interstage stall pressure. Exceeding the inlet pressure over the interstage stall pressure will only cause the compressor to stop and will not result in an accident or malfunction. The compressor will start again when the inlet pressure is reduced accordingly.