Official distributor in Russia and CIS countries

Air treatment for SCUBA diving

Diving Center Selection

Diving attracts with its romance. There is no person who would not want to experience the magic emotions associated with immersion in the sea abyss.

In doing so, we all understand the potential risks and responsibilities associated with this entertainment.

It is vital to trust your safety, your health, your life to true professionals who care.

Is it possible to assess the professionalism and dedication of a diving center while on land?

Each of the diving centers is full of posters, certificates, diplomas, cups and other convincing attributes.

Are there internal beacons that will indicate a diver's high or low professional level?

As representatives of the manufacturer of specialized compressor equipment for medicine, rescue services, the armed forces, aviation, cosmonautics, diving, and at the same time diving, we will tell you one of these beacons.

The air we breathe

When submerged, we take with us the main source of our survival - air.

Let's ask ourselves the question: Where does this air come from? Who prepared it? What equipment is used?

When charging diving cylinders, air is taken from the atmosphere. Compress it with compressors.

There are many types of compressors of various designs for charging cylinders with air. Depending on the quality of the air supplied, the price of compressors with the same characteristics can vary several times and even tens of times.

We will talk about the most popular models among SCUBA diving professionals - the cheapest.

We will also talk about equipment used by diving professionals.

So, you need to charge the diving bottle, it's self-contained underwater breathing apparatus (SCUBA), it's a rebreather.

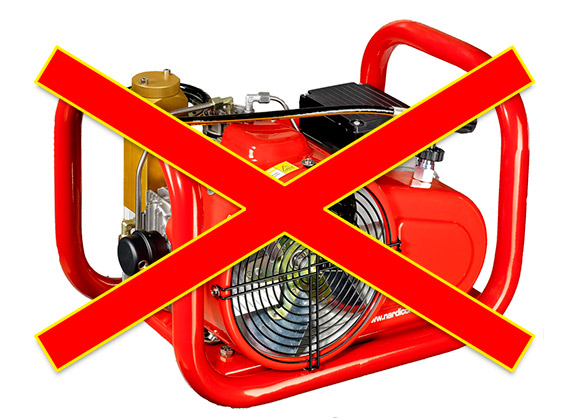

The simplest, cheapest and most efficient equipment is the high pressure oil piston compressor.

Why oil? It is impossible without oil - it lubricates the piston group, preventing its premature wear.

Significant amounts of oil aerosol are discharged with air to the discharge line.

Wear products of the piston group enter the air together with the oil.

Compressors of this type are not designed for medical use, life support, breathing air preparation.

In essence, these are general industrial compressors designed to supply industrial pneumatic equipment with high-pressure air.

The supplied equipment is itself oil-lubricated, so the oil aerosol from the compressor is extremely beneficial to it.

Can a similar diving compressor be used? Not at all, but if very profitable...

To charge diving cylinders, a high-pressure charcoal filter is installed at the compressor discharge to clean air from mechanical contaminants and oil. Coal absorbs oil and moisture, filter elements retain mechanical particles.

The main characteristic of any filter is the fineness of filtration - this is the smallest particle size passed by the filter element. The fineness of filtering to a certain level slightly affects the cost of the filter, then the price rises hopefully.

In astronautics, special filter systems are used that can purify human urine to the quality of drinking water (astronauts do not drink such water for ethical reasons, use it for equipment needs), clean air "from the exhaust pipe" to the level of medical.

Obviously, such systems cost space money and are not used in the general industry.

For ordinary people, a HEPA cleaning class was invented that should convince the consumer that everything is perfectly clean.

As gas preparation professionals, we can argue that no mechanical filter is able to completely clean pumped gas from mechanical particles, much less emulsions.

Filter quality is significantly reduced during filter clogging.

Conclusion: When air is inhaled from the oil piston compressor, we inhale the oil aerosol even when using a new, high-quality, clean filter, during the filter contamination process, the air quality is significantly deteriorated.

What do professional diving organizations use?

For professional deep-sea diving, in addition to air, breathing mixtures are used:

- Oxygen-nitrogen mixture of CAS - Nightrox

- Helium-oxygen mixture GCS - Heliox

- Helium-nitrogen-oxygen mixture GKAS - Trimix

During the preparation of the mixture, pure oxygen is pumped into the cylinder. Contact of pure oxygen with oil even in a small amount will lead to explosion.

Cheap and efficient solutions are no longer suitable, expensive and professional systems are required.

In this case, oil-free compressors in the oxygen version, membrane atmospheric compressors, piston booster compressors are used.

The cleanliness of such equipment is regulated by specialized standards such as ASTM G93-96 and CGA-4.1.

Cost Effectiveness

It is obvious that for amateur diving there is no need for air preparation along with professional underwater work. Different tasks, different underwater times.

The following fact is interesting - the cost of high-pressure oil filters of a high degree of purification is quite high. To ensure safe air quality, they must be installed at least 2 pieces in sequence and often changed. The cost of replacing filters in the future of several years of operation will exceed the cost of professional equipment, which is unacceptable from the point of view of cost efficiency.

The obvious business solution is cost reduction - filter savings.

During internal inspection of cylinders, diving equipment maintenance specialists detect oil rivers in the cylinder. Cleaning liquid becomes black after washing the cylinders.

Effects of compressor oil emulsions on human health

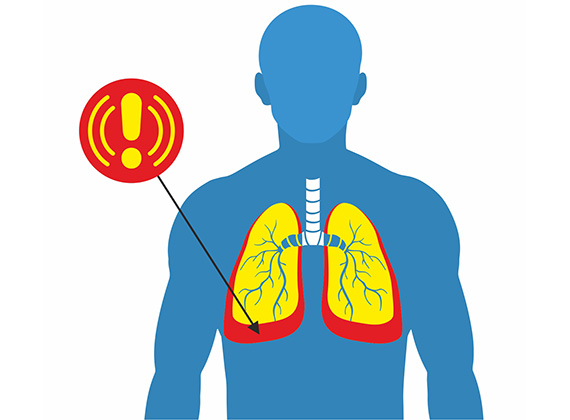

With prolonged exposure to oil emulsions, the following diseases can develop on the human respiratory system: rhinitis, pharyngitis, tonsillitis, bronchitis, vegetative vascular disorders, lipoid pneumonia, respiratory tumors, lung and bronchial cancer.

Purpose of this article

We sincerely hope that the coverage of this issue will encourage industry professionals to improve the quality of services provided, preserve the health of many consumers.

If you still have questions about air preparation, you can ask our specialists by filling out the request form below.

However, we recommend that you ask your diving provider questions first.

Recommended questions:

- What type of compressor is used?

- How often are compressor discharge air filters replaced?

- How many cylinders are charged per day?

- What is the filter life in liters of air per passport?

- You also need to know the volume of cylinders to be charged and the charging pressure.

The answers to these questions will provide an opportunity to quantify the quality of service delivery.

Does the diving specialist claim that there is no oil in the cylinder and everything written above is not true?

Ask him the following question: Is he ready to dump air from the bottle and charge it with pure oxygen?