Official distributor in Russia and CIS countries

Bench for hydraulic testing of brake hoses

The bench is designed for testing automotive brake hoses in large-scale and mass production.

The quality of flexible brake hoses shall be checked by hydraulic tests at a pressure of about 250 bar. Test benches with pressures in the range of 150-300 bar are used to create such conditions, depending on customer requirements.

The test module of the bench may consist of either one or two test chambers for continuous operation - as long as loading occurs in one chamber, brake hoses are installed in the second. The capacity of such a system, designed to accommodate 4 products in each chamber, will be 500-700 thousand units per year.

The module is mounted on a single frame together with the pump part, and the liquid tank equipped with filters is installed nearby.

Stand complete:

- low pressure pump for pre-filling of brake hoses;

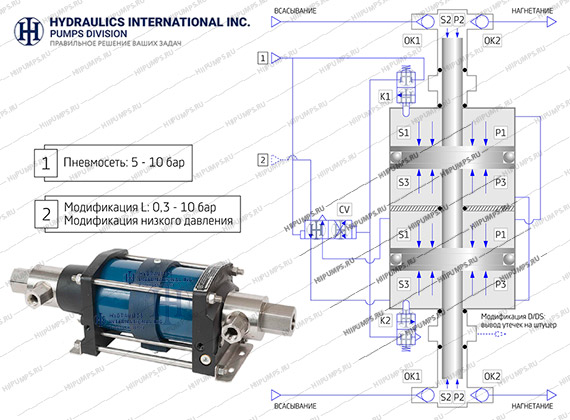

- High pressure pneumatic pump for high pressure generation;

- membrane pump for liquid return to the tank;

- Brake hose drying system after testing to ensure "no drop" drying quality in accordance with industry requirements.

Recording a pressure drop with an accuracy of 0.1% allows detecting the slightest leaks even taking into account the possible deformation and thermal expansion of the tested product.

The bench operation is controlled by the controller PLC and the operator touch panel.

| Operation | Operation Time | Comment |

|---|---|---|

| Pressing the operator test button, starting the test procedure, closing and locking doors | 5 seconds | includes full door closing and locking times |

| Pre-filling and washing of brake hose | 10 seconds | includes valve switching time |

| Pressurizing the hose with a pressure of 250 bar | 6 seconds | includes valve switching time |

| Stabilization | 10 seconds | Pressure Hose Stretch Time |

| Sample isolation from pressure source, pressure drop control, pressure drop over 2% sample rejection signal | 15 seconds | includes valve switching time |

| Depressurization | 4 seconds | includes valve switching time |

| Hose Purge | 10 seconds | purge quality determines hose design and purge time |

| Unlock and open doors | 5 seconds | |

| Total Hose Kit Test Time | 60 seconds | Critical Path Time |

| Total reboot time of the hose set by the operator in the opposite test cell of the bench | 50 seconds | Operator Dependent Time |

| Model | Operating pressure | Filing |

|---|---|---|

| 5L-DD-20 | 20 - 207 bar (2.0 - 20.7 MPa) | 0 - 8.7 l/min max. 32 l/min |

| 5L-DD-30 | 30 - 310 bar (3 - 31 MPa) | 0 - 6.0 l/min max. 22 l/min |

| 5L-DD-60 | 60 - 621 bar (6.0 - 62.1 MPa) | 0 - 3.7 l/min max. 13 l/min |

| 5L-DD-90 | 90 - 931 bar (9 - 93.1 MPa) | 0 - 2.4 L/min max. 4.0 l/min |

| 5L-DD-120 | 120 - 1034 bar (12 - 103.4 MPa) max. 1241 bar (124.1 MPa) |

0 - 1.8 l/min max. 6.5 l/min |