Official distributor in Russia and CIS countries

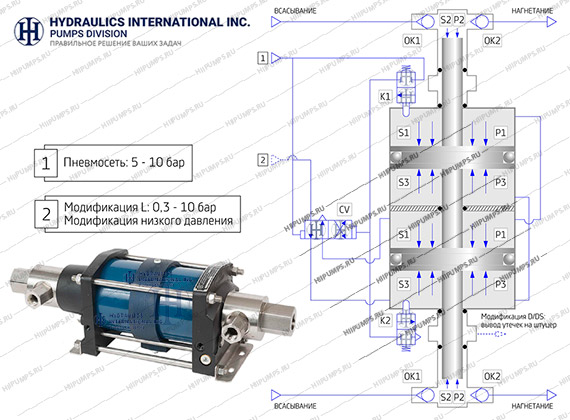

HP Plunger-Type Pumps Series 5L-DD

Main features of 5L-DD pumps

- Drive type: pneumatic

- Pressure range: from 20 to 5,516 bar (2–551.6 MPa)

- Flow range: 0–10 l/min (100 l/min max.)

- Max. flow varies for different models and depends on the operation mode

- Pneumatic drive feeding: 5-10 bar (0.5–1.0 MPa) industrial oil-free air or nitrogen

- Special configurations of drives: fed from oil gas, methane, etc.

- Pressure control: smooth, stepless, with a high accuracy, in a wide range of operation pressures

- Flow control: smooth, stepless, with a medium accuracy, in a wide range of flows

5L-DD Pumps chart

| Pump model | Discharge pressure1. bar / MPa | Flow rate2 |

|---|---|---|

| HII pumps 5L-DD | ||

| 5L-DD-20 | 20 - 207 bar (2.0 - 20.7 MPa) | 0 - 8.7 l/min max. 32 l/min |

| 5L-DD-30 | 30 - 310 bar (3 - 31 MPa) | 0 - 6.0 l/min max. 22 l/min |

| 5L-DD-60 | 60 - 621 bar (6.0 - 62.1 MPa) | 0 - 3.7 l/min max. 13 l/min |

| 5L-DD-90 | 90 - 931 bar (9 - 93.1 MPa) | 0 - 2.4 l/min max. 4.0 l/min |

| 5L-DD-120 | 120 - 1,034 bar (12 - 103.4 MPa) max. 1,241 bar (124.1 MPa) |

0 - 1.8 l/min max. 6.5 l/min |

| 5L-DD-230 | 230 - 2,380 bar (23 - 238 MPa) | 0 - 0.9 l/min max. 3.4 l/min |

| 5L-DD-300 | 300 - 3,100 bar (30 - 310 MPa) | 0 - 0.7 l/min max. 2.6 l/min |

| 5L-DD-410 | 410 - 4,240 bar (41 - 424 MPa) | 0 - 0.51 l/min max. 2.00 l/min |

| 5L-DD-600 | 600 - 5,516 bar (60 - 515.6 MPa) | 0 - 0.35 l/min max. 1.3 l/min |

Features of 5L-DD Pumps

5L-DD pumps can be universally used for most applications where pneumatically driven pumps are feasible.

Due to a double pneumatic drive, the pumps have maximum performance in this pressure class.

A double hydraulic part provides minimum pressure fluctuation in the HP line as well as higher performance.

The hydraulic part is made of corrosion resistive materials to convey aggressive and chemically active liquids, including alkalis, acids, solvents, and chemicals.

The pneumatic drive is fire-safe—this is a perfect solution for conveying fire-hazardous, flammable, and combustible liquids.

Applications

- Hydraulic testing of large capacity equipment (up to 10 m3 and higher)

- Feeding of hydraulic drives (up to 10 l/min)*

- Supply of liquids to process (up to 10 l/min)*

*Please note that any pneumatically driven pump has a significantly lower rated flow than the rated flow of electrically driven pumps.

Examples of 5L-DD pump applications

Example 1: hydraulic pressure testing of small and medium capacity pressure vessels.

In principle, hydraulic pressure testing should be performed in three stages: connecting-up the pump, setting the pressure, and pressurization.

No automatic control, bypassing, or liquid heating is needed.

Due to a high discharge pressure repeatability, a test run can be carried out without re-setting the equipment.

A protection against operator mistakes (mistake-proofing) reduces operation risks to zero.

Example 2: feeding hydraulic equipment and tool drives.

5L-DD pumps are perfect for feeding hydraulic drives of presses, clamps, gripping tools, and other tools where a pre-set static force is required.

The hydraulic pressure, and consequently, the force are controlled by a pneumatic drive feed pressure setting.

By increasing or decreasing pressure in the LP pneumatic line with an air throttle valve, you can set the required force with a high degree of accuracy.

The pump runs without bypassing, and there are no excessive energy losses or operation fluid (oil) heating.

Example 3: hydraulic pressure testing of large capacity vessels.

For hydraulic testing of HP vessels, it is required to use a combination of an electrically driven high flow pump to run in the pre-filling and fast pressurization mode and a 5L-SD pump to maintain pressure in the equipment for a long time (from several hours to several days).

Running in this mode, a 5L-DD pump will automatically maintain the required discharge pressure with a minimum power consumption, without heating the liquid.

Example 4: cyclic testing of small capacity equipment with a high cyclicity.

HP hoses with a small filled capacity should be cyclically tested, the number of load cycles per one test is one million.

A 5L-DD pump in combination with a simple automation control system will help load a HP hose, ensure high repeatability, and minimize the liquid heating effect.

5L-DD pumps are designed to run with high cyclic loads.

Example 5: supply of HP liquids to process

Due to a double-plunger design of the hydraulic part, 5L-DD pumps provide minimum pressure fluctuations that may be achieved with the equipment of this class, so a stable and constant pressure can be maintained in the discharge line, even at high flows.

An optional hydraulic pressure reducer may be installed at the pump discharge to reduce the fluctuation to zero and to maintain a stable and constant pressure in the line with a high degree of accuracy.

5L-DD pumps are successfully applied for feeding HP nozzles, HP liquid injection, and supply of chemicals to process.

Please note that pneumatically driven pumps maintain a stable and constant pressure, but do not provide a constant flow while running, so they cannot be applied for high accuracy dosing of liquids.

Advantages

- No contamination of conveyed liquids — a perfect solution for pumping high purity liquids

- A perfect solution for pressure control: in some running modes, these pumps are extremely more efficient than electrically driven pumps

- No liquid heating effect in any running mode — no heat exchanger required

- No bypass valve or pressure-relief valve required

- No need for a VFD — “automized” control without automation devices

- Unlimited number of start and shutdown cycles—a perfect solution for applications with high cyclic loads

- Resistant to water hammer effects caused by hydraulic fracture of the equipment

- Extremely smooth and easy flow and pressure delivery control in a wide range: from zero to max values, with no special skills required from an operator

- No electric equipment is needed

- Fire- and explosion-proof

- Long dry running and cavitation resistant

- High self-suction capabilities

- Compact and lightweight: a portable solution

- Minimum flow fluctuation due to double-plunger design

Restrictions

- Not applicable for conveying contaminated liquids and liquids with mechanical impurities

- Restricted usage for high flow applications

- Much more expensive than the electrically driven equivalent solutions for such applications as flushing and pressure testing of equipment with a capacity of over 100 m3, as well as for pre-filling of large capacity equipment and systems, where high flows are constantly required

- Not applicable for gas handling

- Not applicable for high accuracy dosing

Liquids

- Pure water, industrial water, oily water, water containing corrosion inhibitors

- Distilled water, deionized water

- Industrial oils, hydraulic oils, aircraft oils, mineral oils, synthetic oils, motor oils, loom oils

- Break fluids, Skydrol

- Hydrocarbons, solvents

- Antifreeze compounds, ethylene glycol, non-freezing liquids

- High-purity liquids

- Explosion hazardous liquids

- Chemically active and aggressive liquids