Official distributor in Russia and CIS countries

Fogging system for greenhouses

Fogging system KGS-STEAM-M1-200-30-L for greenhouses

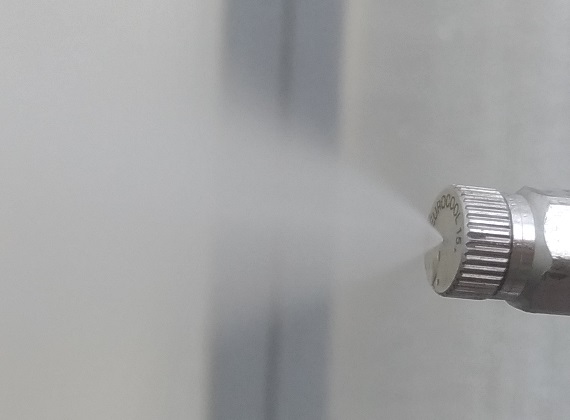

Model range of KGS-STEAM fogging systemsFogging system KGS-STEAM-M1-200-30-L will provide optimal conditions for rooting cuttings in an environment of artificial fog, growing mushrooms, vegetables and ornamental crops.

Fog of pressure class 100-300 bar is close in characteristics to natural morning fog, slowly precipitates, on average it is fixed in the air from 60 to 120 seconds, depending on the operating pressure.

Fog 100-300 bar moistens the sheet well, provides optimal nutrition of the sheet, while not forming drops on the sheet.

Fog 100-300 bar moisturizes the soil well, but it does not water it, does not wash out fertilizers and trace elements from the soil.

For crops requiring an even thinner and almost dry mist, we recommend considering KGF-STEAM installations of a higher pressure class, generating micro-fog of a pressure class of 300-600 bar: Model range of KGF-STEAM fog generation systems

Minimum equipment of the KGF-STEAM-M1 fog generation system-200-30- L

- Hydraulic pump with pneumatic drive, model

- Low pressure line:

- Water connection fitting G3/4"

- Mechanical filter at the input of 10 µm

- High pressure line:

- Mechanical pressure gauge OR digital pressure gauge OR discharge pressure converter for monitoring the supply pressure of injectors

- Plug for residual pressure relief and system pumping

- High pressure nozzle for feeding misting nozzles

- High pressure tubes and fittings – pressure class not less than 300 bar

- Pneumatic pump drive control line:

- Air source connection fitting

- Mechanical dust filter/oil/dehumidifier with automatic condensate discharge

- Solenoid valve (220V/12V/24V) for automatic control OR manual pump control valve

- Mechanical pressure gauge OR digital pressure gauge OR pressure converter OR pressure indicator for monitoring pressure in the pneumatic network

- Housing:

- Welded semi-open/closed stainless steel frame. steel (standard)/aluminum (optional) with main control panel and side panels.

- Optional: Intelligent control panel design.

| Pump Model | 5L-SD-30 |

| Number of pumps in the unit | 1 |

| Drive Type | pneumatic |

| Type of hydraulic part | single plunger |

| Operating pressure | 60 – 500 bar |

| Pump performance: | |

| Constant mode of operation (24x7) | 0 – 2.5 l/min |

| Cyclic operation mode | up to 5 l/min |

| Number of simultaneously fed nozzles 0.15 mm: | |

| Constant mode of operation (24x7) | 1 – 17 pcs |

| Short-term cyclic operation | up to 34 pcs |

| The rate of humidification of indoor air: | |

| Constant mode of operation (24x7) | 0 – 6500 m3×%/min |

| Short-term cyclic operation | up to 13000 m3×%/min |

| Recommended room volume: | |

| Fine-grained irrigation, artificial fog in greenhouses | up to 1500 m3 |

| Humidification and cooling of objects with intensive ventilation | up to 3000 m3 |

| Humidification and cooling of objects with moderate ventilation | up to 13000 m3 |

| Humidity range | 30 – 100 % |

| Modification code | Description |

|---|---|

| STAINLESS STEEL.TANK | Stainless steel tank as part of the installation A 50L stainless steel tank as part of the installation housing (the volume may vary depending on the dimensions of the housing, layout, customer requirements), equipped with pressure relief fittings, liquid supply, drain, overflow. Filler neck with filter assembly. The top cover is removable – allows easy cleaning of the inner surface of the tank. |

| B1 | Pressure relief valve Pressure relief valve for pumping the system at the first start and after maintenance, relief of residual pressure. Installed instead of a pressure relief plug |

| FVD | High pressure filter Mechanical high-pressure filter of 5 µm as part of the installation. Not required. |

| 2K | Valves for manual And automatic control of the pneumatic pump Solenoid valve (220V/12V/24V) for automatic control and manual pump control valve installed in parallel. Provide manual redundancy of the pump pneumatic drive control. |

| T | Pump start/stop timer The pump start/stop timer provides automatic start/stop of the pump in time without additional control systems |

| HOLD | Hydraulic power management module for injectors

The hydraulic power management module of the injectors includes a high-pressure valve with a pneumatic actuator, a solenoid valve for controlling the valve. The block does not include an automated control system (see the AUTH option). The module can also include an additional pressure converter/pressure indicator/ digital or mechanical pressure gauge to monitor the current state. The module allows you to get a tougher performance and, accordingly, a better fog at the beginning and end of the feed cycle. |

| ZI | Pump sound insulation Casing of the housing with sound-proof material to reduce the noise level of the pneumatic pump drive. |

| pc | Safety valve as part of the installation In most cases, a safety valve is not required as part of the installation. The pump in the installation is physically unable to exceed the maximum discharge pressure and thereby cause damage to equipment and personnel. |

| AUTH | Integrated automation system The system of complex automation is developed individually according to the requirements of the customer. Depending on the complexity of the task, we reserve the right to provide the service on a paid basis. |

| COMPR | Feeding compressor Feeding air compressor 8 – 10 bar as part of a comprehensive equipment order. As a rule, the compressor is not mounted in the installation housing and is located separately. Installation of the compressor in the housing can lead to a significant increase in the cost of the system. |

CLEAN | Water treatment system as part of the installation Integrated water treatment system in accordance with the customer's technical specifications. |