Official distributor in Russia and CIS countries

Mobile unit for hydraulic testing of oil and gas equipment

Field tests of tanks, pressure vessels, tanks, pump and compressor equipment housings, reactors, pipelines, packers

Model range of mobile units for hydraulic testing KGF-TEST M1 series

Mobile installation for hydraulic testing of oil and gas equipment KGS-TEST-M1-700-90- XL based on the HII 5L-DD-90 pump is designed for field testing of high pressure tanks, pressure vessels, columns, pump and compressor equipment housings, reactors, pipelines, packers during repair and maintenance in the pressure range 250-700 bar.

Specifications:

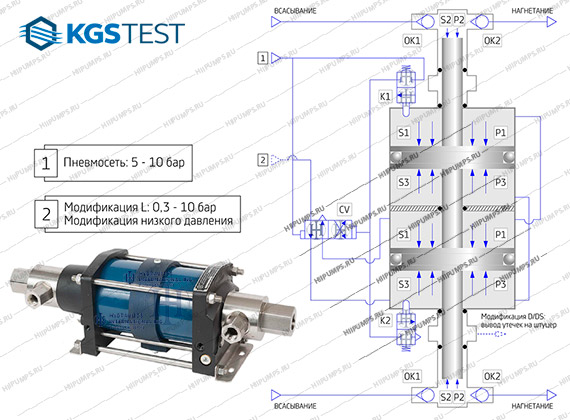

- Air driven liquid pump model 5L-DD-90

- Power elements of the pneumatic pump drive:

- Through fitting for connection to the pneumatic network – mounting on the side panel

- Mechanical air filter-oil separator

- Pressure reducer – mounting on the control panel

- Start-stop/pump speed adjustment valve – mounting on the control panel

- Low pressure line:

- Through fitting for connection to the water supply – mounting on the side panel

- Mechanical suction filter ½" 10 microns, 7 bar

- High pressure line:

- Mechanical pressure gauge on discharge: front flange for panel mounting, dial 160 mm, scale 0-1000 bar, accuracy class 1%, NPT fitting, measuring range (25-75%): 250-750 bar

- Discharge fitting – mounting on the side panel

- Pressure relief valve without protection from mechanical contamination, outlet to the drain fitting

- High pressure tubes and fittings 1/4" – pressure class 700 bar

- Installation body: welded semi-open/closed stainless steel frame. steel with main control panel and side panels

- All controls and fittings are placed on the panel

- Intelligent design of control panels, signatures in Russian

| Pump Model | 5L-DD-90 |

| Number of pumps in the unit | 1 |

| Drive Type | pneumatic |

| Type of hydraulic part | two-plunger |

| Type of pneumatic part | two-piston |

| Multiplication factor | 90 |

| Range of discharge operating pressures | 90-931 bar |

| Maximum allowable pressure in the pneumatic network | 10.3 bar |

| Recommended pressure in the pneumatic network | 5-8 bar |

| Minimum pressure in the pneumatic network | 2 bar |

| Feed per cycle | 40.6 ml/cycle |

| Flow | 0 - 2.4 (9.0) l/min |

| Maximum permissible fluid pressure at the inlet fitting of the installation | 7 bar |

| Recommended fluid pressure at the inlet fitting of the installation | 3 bar |

| Minimum fluid pressure at the inlet fitting of the installation | atmospheric |

| Operating temperature range of the pneumatic actuator | -12 °C ... +65 °C |

| Operating temperature range of the hydraulic part | +3 °C ... +40 °C |

| Modification code | Description |

|---|---|

| TANK | Stainless steel tank as part of the installation A 50L stainless steel tank as part of the installation housing (the volume may vary depending on the dimensions of the housing, layout, customer requirements), equipped with pressure relief fittings, liquid supply, drain, overflow. Filler neck with filter assembly. The top cover is removable – allows easy cleaning of the inner surface of the tank. |

| HPF | A mechanical high-pressure filter as part of the installation to protect the pressure relief valve A 5 µm high-pressure filter to protect the pressure relief valve will ensure reliable and long-lasting operation of the valve sealing needle even when testing heavily contaminated products (the reason for 90% of non-warranty valve failures in the first month of equipment operation). |

| LPFP | Pneumatic diaphragm pre-filling/feed pump with individual air control system ½” The pneumatic diaphragm pump for pre-filling and feeding the high-pressure pump will allow you to quickly fill the product before the start of the test and provide the required pressure at the suction of the high-pressure pump, which guarantees its stable operation. The package includes: A ½” 0-50 l/min pump, a start-stop valve, pump speed adjustments, a pneumatic drive supply pressure regulator, a pressure indicator in the pneumatic network, a discharge pressure indicator. |

| HPFP | High pressure feed pump with individual pneumatic control system The 3L-SS-25 high-pressure feed pump will provide unloading of the main pump and significantly reduce the cyclic fatigue of the hydraulic part. It is recommended for highly loaded working conditions. The package includes: HII series 3L pump, start-stop valve, pump speed adjustment, pneumatic drive supply pressure regulator, pressure indicator in the pneumatic network, high pressure pressure gauge on discharge, high pressure relief valve on discharge. |

| SAPR | Safety air pressure reducer Safety air pressure reducer in pump air drive line allows for precise adjustment and control of the discharge pressure limitation by the operator in a constant mode, eliminating operator error. It is especially relevant for monotonous testing of products of various pressure classes (the reason for 80% of the destruction of the product is due to operator error). |

| V2M2 | Isolation valve + backup high pressure gauge An isolation valve is necessary to cut off the product from the main line to control the tightness of the product. Check valves, as the pump wears out, may not provide the required level of tightness and may introduce an error in measuring the rate of pressure drop. After the isolating valve, a duplicate pressure gauge is installed, according to which the pressure drop in the product is monitored. The high-pressure line to the valve must be unloaded when checking the tightness of the product. This ensures that there is no compensation for leaks with the pump turned on through the needle of an incompletely closed insulating valve. The B2M2 modification will allow for full-fledged leak tests and micro leaks without installing additional measuring instruments. |

| SVHP | Safety valve as part of the installation In most cases, a safety valve is not required as part of the installation. The pump in the installation is physically unable to exceed the maximum discharge pressure and thereby cause damage to equipment and personnel. When choosing methods to ensure the safety of tests, we recommend giving preference to the modification of the LPR. |

| GFG | Pressure gauge with glycerin filled housing Reduces fluctuations of the pressure gauge needle with a sharp set and pressure relief. Increases the resistance of the pressure gauge to shock pressure surges. attention: as standard, including modifications MAX, GFG, the pressure gauge is not protected from water hammer during hydraulic rupture of the product. Special equipment is required for hydraulic rupture tests. Consult with our specialists. |

| MAX | Pressure gauge with maximum pressure arrow Pressure gauge with maximum pressure arrow. Allows you to record the maximum pressure values during dynamic loading, including during hydraulic rupture of the product. ATTENTION: as standard, including modifications MAX, GZM, the pressure gauge is not protected from water hammer during hydraulic rupture of the product. Special equipment is required for hydraulic rupture tests. Consult with our specialists. |

| NSGS | Non-standard high pressure gauge scale Non-standard gauge scale, including double scale, non-standard measurement ranges, non-standard values, non-standard division price. |