Official distributor in Russia and CIS countries

Refrigerant pumps and boosters

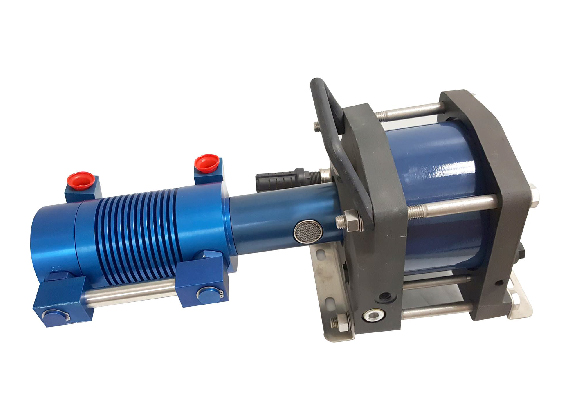

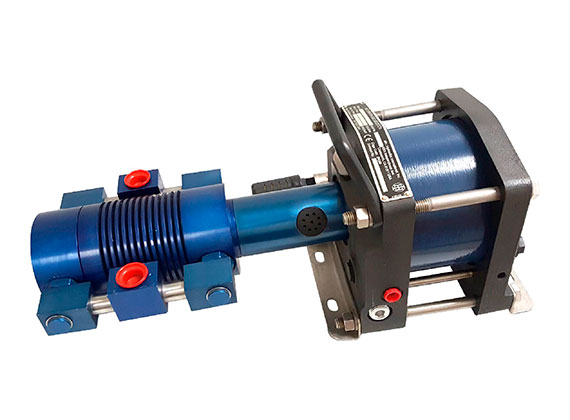

Multiphase Pump Compressors for Freon Transfer

Compressor pumps HII in standard and special versions are designed to pump freons R11, R12, R13, R14, R134a, R22, R600a, R407c, R410a, ammonia NH3 and others.

Multiphase pump compressors are HII designed to pump freons in any phase from 100% gas to 100% liquid. Therefore, they can simultaneously perform the function of a pump and a compressor. At the same time, no operator actions are required - the compressor takes the freon in the phase in which it comes. The phase state actually only affects the freon transfer rate.

Rule 3 to 100: The rate of transfer of freon in 100% liquid phase is 100 times higher than the rate of transfer of freon in 100% gas phase.

The line of standard freon pump compressors is represented by 5 basic models for solving 80% of typical consumer tasks related to pumping unstable multiphase media, but can be supplemented by a line of hydraulic pumps and pressurizing gas compressors depending on the task.

Some models of pump compressors are designed to swing freons to a deep vacuum of 500 mm Hg, which allows you to swing the gas phase of the freon to zero.

Pump-compressors HII can be used to pump out-of-service freons, special freons, problem gases such as carbon dioxide, hazardous, chemically active media.

Also, compressor pumps are able to liquefy freon with pressure in the subcritical temperature area.

Ideas for Freon Pump Compressors

Filling of small cylinders from a special container or ISO tank.

Swing the freon gas phase from an empty container (special container or container) to full.

Swing freon from the refrigerated equipment to the intermediate container to save expensive gas.

Transport of Freon liquid phase from one container to another.

Cost effectiveness of freon compressors for gas phase rocking

The economic feasibility of swinging the freon liquid phase is obvious.

The weight of the gas phase is not so noticeable, so it is often neglected.

In fact, with a gas phase, at least 20 kg of freon is lost from one 900-liter barrel.

Our specialists calculate the cost-effectiveness of rocking taking into account equipment wear, costs for repair kits, etc.

Calculations show a payback of 10 to 100 times for almost all freons at high residual pressure (start of rocking) and 2 to 10 times under high vacuum.

Often a freon compressor pays off from the first 10 barrels.

Send a request and our experts will offer you the best solution to save your money.

Specifications

- Drive type: pneumatic;

- Pressure range: 0 to 86 atm standard, 2000 atm maximum (0-8.6/200 MPa);

- Hydraulic part type: single/double piston;

- Number of stages: single-stage/two-stage;

- Freon inlet phase state: from 100% liquid phase to 100% gas phase;

- Freon injection phase state: from 100% liquid phase to 100% gas phase;

- Hydraulic (gas) part lubrication: dry, oil-free - works without lubrication, does not contaminate freon;

- Air drive grease: grease;

- Type of rod seal: double, with unloading chamber;

- Pressure range: 5 to 86 atm standard, 2000 atm maximum (1 - 8.6/200 MPa);

- Minimum inlet pressure: vacuum 500 mm. rt. Art.;

- Maximum inlet pressure is determined by the model equal to maximum discharge pressure;

- Liquid phase capacity: 0-20l/min (100 l/min maximum);

- Maximum Gas Phase Capacity: depends on operating mode;

- Pneumatic drive power supply: 5-10 atm (0.5-1.0 MPa);

- Pressure control: smooth, stepless, medium/high precision, in a wide range of operating pressures;

- Flow control: smooth, stepless, medium/low precision, over a wide range of flow rates.

Benefits

- Clean gas design - no lubrication;

- Do not contaminate gas - ideal for pumping high-purity gases;

- Unlimited number of start-up, shutdown cycles - designed for hard cycle load operation;

- Smooth, easy adjustment of supply and delivery pressure in a wide range from 0 to MAX;

- Do not require any electrics - fire and explosion-proof;

- Compact and lightweight - mobile solution;

- Transfer from 100% gas phase to 100% liquid phase;

- No cavitation restrictions by definition;

- Possibility of gas liquefaction by pressure;

- Ability to swing gas to significant vacuum values.

- Inert to dust, moisture, weather;

- Fire - Explosion Proof

- Easy to operate, maintain, manage, repair.